Imagine that someone makes a business proposal that would significantly improve your company’s cost productivity. The sales pitch is appealing. This approach is claimed to have the following potential benefits:

- It will yield over 4 times your investment in bottom-line results within 24 months, with a long-term ROI exceeding 7x.

- It does not require any capital.

- It will enable the development of a broad range of skills for key employees.

- It will be the basis for culture change to a continuous improvement mindset.

Sounds great! Where do I sign up? But this is what you will not hear…

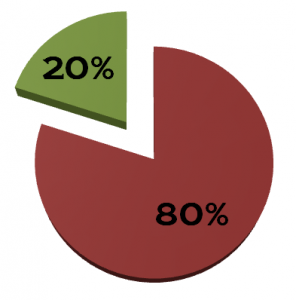

- It only has a 20% chance of succeeding!

Given this success metric, would you make this investment? It’s not likely.

Lean Six Sigma (LSS) has the potential to produce all the positive benefits itemized above. However, the success rate of deployments is abysmal. In a Bain & Company management survey of 184 companies, 80 percent say their Lean Six Sigma deployment efforts are failing to drive the anticipated value, and 74 percent say they are not gaining the expected competitive edge because they haven’t achieved their savings targets. Other surveys reveal similar disappointment or disillusionment in LSS by executives and senior leaders.

The bad news is that 8 out of 10 LSS deployments are not meeting expectations. The good news? Some organizations are “getting it right” and reaping the benefits of a strong Lean Six Sigma deployment.

I was part of an extremely successful LSS deployment that achieved significant and lasting improvements. I believe there are some key enablers of this success:

- Leadership engagement & commitment

- Diverse problem-solving methods

- Proactive, engaged champions

- Full time, respected black belts

- Trained green belts as project leaders

- High impact project selection

- Financial evaluation system

- Metrics & goals linked to business objectives

- Project tracking system

- Strong mentoring & coaching

Leadership engagement & commitment

It all starts here. You need a senior leader who can be a true executive sponsor for LSS. This is especially critical during the early stages of the deployment, when you are recruiting the first classes of Black Belts (BBs). It makes a difference when the President or CEO consistently states that LSS is one of the key enablers of our strategy. Additionally, when the chief executive strongly suggests that the path to future leadership positions goes through a black belt tenure, it sends a powerful message.

Diverse problem-solving methods

LSS is not just DMAIC. It is important for the Black Belts to learn about other process improvement methods that can be used to solve a variety of problems as part of the Lean Six Sigma deployment. They also need to be skilled at leading Kaizen events and leveraging specialized methods such as Quick Change-Over, Mistake-Proofing, and Rapid Action Tools®.

Rapid Action is an especially powerful part of any continuous improvement method because experienced project leaders are not necessary to drive significant business improvements. You can leverage people who are closest to the work and use a structured method to get real results in 60 days or less! In the deployment that I led for eight years, over 1/3 of all projects were completed using the Rapid Action methodology.

Basic tools of Innovation are also valuable additions to the toolkit. These methods can produce some “quick wins” with visible results and/or significant cost savings, which builds credibility with the process owners.

Proactive, engaged champions

Process Champions are critical to connecting the needs of the business with the talents of those who can solve problems. They determine the strategy that determines the priority of what should be addressed. They partner with the Master Black Belts (MBBs) to assess the queue of projects and prioritize the work. Effective process champions generate a natural “pull” for project leaders from the trained belt community.

Full time, respected black belts

The adjectives used to describe this factor are critical. “Full-time” means just that. If the BB is not dedicated fully to driving projects and mentoring others, she finds herself trying to squeeze in some project work at the end of the day (or week). “Respected” is an attribute that is also crucial. The LSS group should be populated with seasoned employees who have earned the respect of their peers. Joining the ranks of the BB team should be seen as a privilege – not as a place to send employees who have not been successful in the organization. To assure that the most qualified BB candidates are selected, use a panel of executives to interview each person before they attend their first LSS training class.

Trained green belts as project leaders

To drive engagement and leverage other leaders in the organization, Green Belt (GB) training is a core part of the Lean Six Sigma deployment. Done well, this provides a continuing education opportunity for many employees, while also accomplishing some significant process improvements as part of their training project. To change the culture, every employee should be enabled to contribute to improving the work that they do. Green Belt training (and Rapid Action training) is a way to provide basic improvement skills to selected salaried employees.

High impact project selection

What are some of the most challenging problems that you are facing? What keeps you awake at night? What will prevent you from meeting productivity, quality, or safety goals? These should be the high-level starting points for a discussion between the Process Champion and the MBB or BB about scoping possible opportunities. High impact project selection is not an academic exercise. It is the essence of working on things that matter.

Financial evaluation system

It is essential to have a standardized method to track any financial savings (hard, soft, or working capital). But just having a method to track the savings is not enough. It is equally critical that any savings are validated by someone in the financial community – not the project leader. This maintains the credibility of the savings reporting. The BB or GB reports the process improvements; the financial representative converts the process metric into dollars.

Metrics & goals linked to business objectives

What do you need to achieve as a business this year to be successful? What are the most significant challenges facing you in the next three years? When selecting projects and setting personal goals, there should be a clear link between the improvement and how this will help the business to succeed. Start with a vision. Then frame a business challenge that you need to achieve within the next 1 – 3 years. After assessing our current state and establishing an interim goal, you can identify the key obstacles that prevent you from meeting the challenge. (More on this approach in a later post). A classic tool that we often use is Goal Means Flow Down (GMFD). Start at the highest level with the business goal and drill down until you have specific measurable drivers for that goal.

Project tracking system

Project management is an essential skill that is required to be successful. Depending upon the size of the Lean Six Sigma deployment, there could be hundreds of active projects. You need a system to track progress on each project, while making sure that the discipline of the project methodology (such as DMAIC) is followed. A visual scorecard of the projects by methodology is helpful in seeing where intervention or more active mentoring is required.

Strong mentoring & coaching

Not every BB is a strong mentor or coach. In conversations with BBs who have repatriated back into the business, most of them admit that one of the most challenging (and rewarding) parts of their black belt role was mentoring. It takes a special skill set to influence someone, as opposed to giving them direction as their supervisor. Skill development on coaching and mentoring are essential for BBs to be successful. In addition, you need to dedicate a portion of the education for BBs on soft skills such as communication, personality styles, and group dynamics.

The ten factors listed here form the foundation for launching and sustaining a successful Lean Six Sigma deployment. These do not guarantee success. But this is certainly a useful checklist for anyone who is seeking to establish a vibrant continuous improvement process in their organization.

Very interesting post. Research I conducted in grad school showed similar results. If an organization “gets it right,” the financial outcomes can be very positive. A link to the paper: http://arno.unimaas.nl/show.cgi?fid=10436

[…] outlined in an earlier post, there are many success factors for an LSS deployment. However, it is not enough to ‘check the box’ on leadership engagement, proactive […]