Sustainable culture change is difficult.

A common view is that the work required to shift the mindset of any large organization is largely the responsibility of leadership. To be sure, the senior leaders of the organization are accountable for setting the vision and supporting it by what they say and do. Unfortunately, many leaders approach this challenge by delivering a message via well-written power point slides to the masses. The assumption is that all they need to do is explain what the company is about and how everyone should be aligned to be successful. And perhaps for a short while this strategy results in an uptick in the “hoped-for” behaviors.

But it does not last. Soon enough, most of the employees slip back into their comfort zone. They see no reason to change anything. “After all,” they think, “This too shall pass. If I wait long enough, someone else will come along with a different flavor-of-the month. Maybe that one will taste better.”

There are many reasons for failing to get an entire organization aligned and to accept a new way of thinking and acting. I will focus on a single consideration.

We accept change at different rates

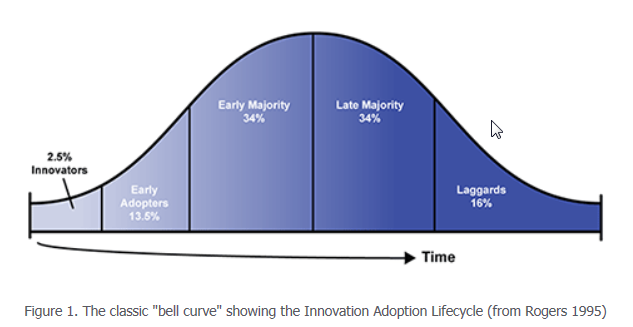

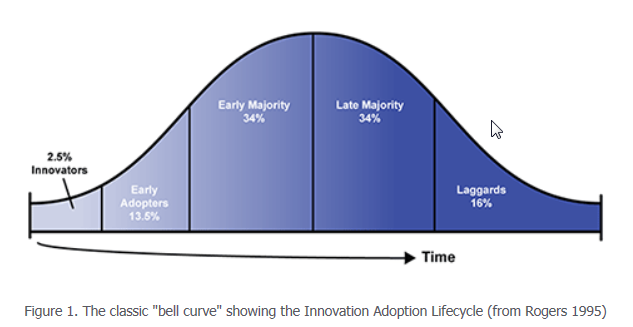

Everett Rogers published his theory on the Diffusion of Innovations in 1962. It is a theory that seeks to explain how, why, and at what rate new ideas and technology spread through cultures. The book (now in its fifth edition) says that diffusion is the process by which an innovation is communicated through certain channels over time among the members of a social system. The innovation or idea must be widely adopted in order to self-sustain. Within the rate of adoption, there is a point at which an innovation or idea reaches critical mass. The people in any  social system who are exposed to the new idea can be placed in segments, depending upon their willingness to adopt the new idea or accept change. Rogers named five categories of “adopters” : Innovators, Early Adopters, Early Majority, Late Majority, and Laggards. These categories are depicted in this graphic.

social system who are exposed to the new idea can be placed in segments, depending upon their willingness to adopt the new idea or accept change. Rogers named five categories of “adopters” : Innovators, Early Adopters, Early Majority, Late Majority, and Laggards. These categories are depicted in this graphic.

Continue Reading

Everyone was given the same materials and a solid rocket engine. On “launch” day, the model rockets were ignited on the football field. All the rockets hurtled skyward for several hundred feet before the fuel was exhausted and they floated back to earth. Except for one. Greg and his lab partner’s rocket whistled out of sight – never to be seen again. When quizzed about what he did, Greg just shrugged his shoulders and said, “I just changed a few things that I thought could make it go higher. I guess it worked.”

Everyone was given the same materials and a solid rocket engine. On “launch” day, the model rockets were ignited on the football field. All the rockets hurtled skyward for several hundred feet before the fuel was exhausted and they floated back to earth. Except for one. Greg and his lab partner’s rocket whistled out of sight – never to be seen again. When quizzed about what he did, Greg just shrugged his shoulders and said, “I just changed a few things that I thought could make it go higher. I guess it worked.”